Maintaining a bell

Maintaining and preserving your architectural heritage

Throughout the year, bells are used regularly. On average, a swinging bell makes 60 back and forth movements per minute. A two-minute Angelus repeated three times a day equals a minimum of 131,400 swings and clapper strikes in one year of operation.

Bodet Campanaire: From bell restoration to maintenance

Bodet Campanaire, the only bell restoration company in France, can work on the bell, the headstock/yoke and the clapper. Our experts study each restoration or manufacture project to ensure our products (clappers, headstock/yokes) are effective and suited to your bell tower.

Our fully bespoke products respect bell craftsmanship and your architectural heritage. Our technicians visit your site annually to check the areas of vigilance on the bell.

Unique know-how in France: Bell Restoration

Since 1991, our welders have restored more than 1,500 bells. Our exceptional weld restoration process requires strict attention to detail, following a traditional method established over 25 years ago. Heating in a kiln, material refill, controlled cooling - bell restoration is meticulous work. An economic solution that gives a second life to your bells. Let’s preserve history together.

Effectively equipping your bell:

Headstock / yoke, clapper, we are experts in working on the bell and its fittings. Restoration or manufacture, all the work is done in our workshops. All products are made to order according to the traditions of bell craftsmanship. Our goal is to guarantee you long-lasting equipment that remains operational over time.

Regular inspection of your bell towers

Often poorly understood by the public, bell towers contain a range of different bell equipment. These buildings are often old and poorly maintained, so can be hazardous to operate. We offer annual inspections of your bell towers to diagnose problems and suggest sensible solutions. Our experts are committed to providing suitable, functional, quality solutions.

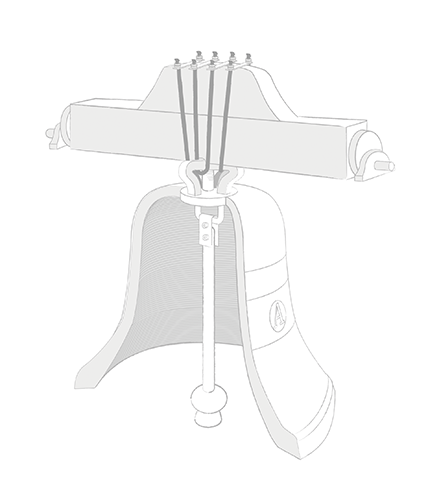

Components of a bell

Headstock / Yoke

Part made of oak or metal on which the bell is hung and swung, in a specific axis.

More informationCanons

Used to hang the bell on the headstock by means of ties

More informationClappers

Suspended inside the bell by the baldric. The clapper strikes the side of the bell when it is swung to produce the ring.

More informationSuspension straps

Flat or round metal parts used to hang the bell from the headstock

More informationCrown staple

Used to hang to clapper

More informationBaldric

Used to hang the clapper from the crown staple inside the bell

More information

Bodet Campanaire: + than 1,500 bells restored

In 2012, the company celebrated its 1000th restoration with a remarkable project in Saint-Emilion (33). Every year, around 100 bells come to our workshops in Trémentines (49) to be restored to their original condition. Cathedrals, churches, basilica, abbeys or private bells, Bodet Campanaire repairs and restores your bells to preserve the history of your towns and villages.